Centre of Industrial Simulation and Prototyping

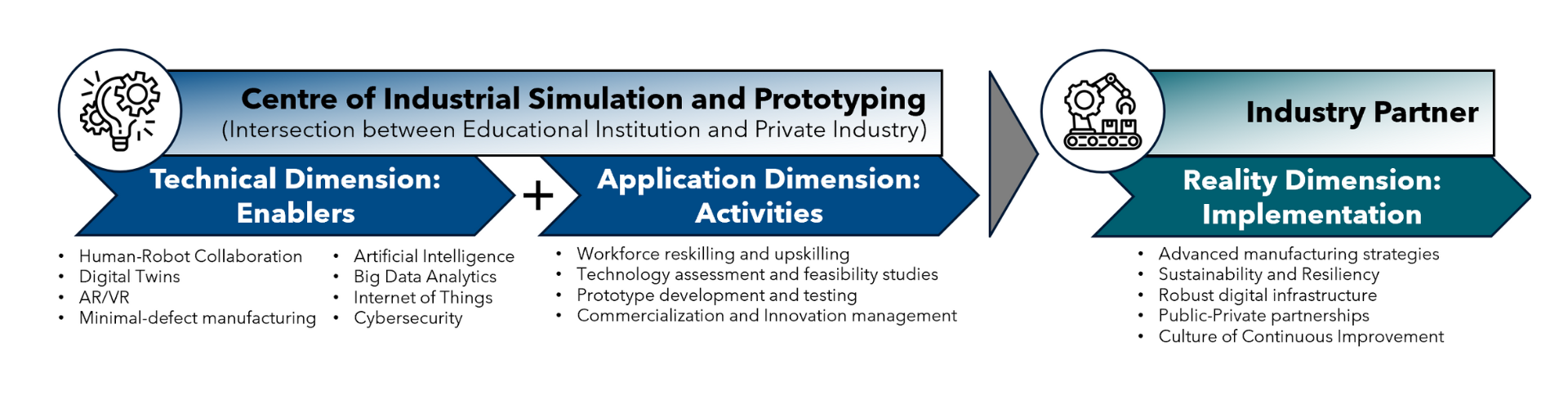

The Centre of Industrial Simulation and Prototyping at Georgian College is the first Industry 5.0 sandbox in Ontario, driving innovation in advanced manufacturing and digital technologies. The centre collaborates with regional manufacturers, vendors, businesses, and community partners to use advanced technology to further drive economic growth in the sector.

Discover the power of collaboration. Learn more about working with us today!

About the centre

Launched in 2024, the Centre of Industrial Simulation and Prototyping supports businesses with resources, expertise and technologies like artificial intelligence (AI), the internet of things (IoT), and advanced tools and technologies to foster sustainable and human-centred manufacturing. The centre is projected to create 500 jobs and position Central Ontario as a leader in advanced manufacturing.

The centre focuses on driving innovation, sustainability and economic growth in advanced manufacturing. It helps businesses adopt cutting-edge technologies like AI, IoT, and collaborative robots while offering advanced simulation and prototyping facilities to support research and development and innovation. It also equips the workforce with skills in Industry 5.0 methodologies, promotes sustainable manufacturing practices, and fosters collaboration among regional partners. By enabling businesses to optimize processes and develop new products, the centre strengthens local supply chains, creates jobs, and positions Central Ontario as a leader in industrial innovation.

Georgian’s Research and Innovation department was recognized for its innovative research and development and for having a high impact on the college and in the City of Barrie.

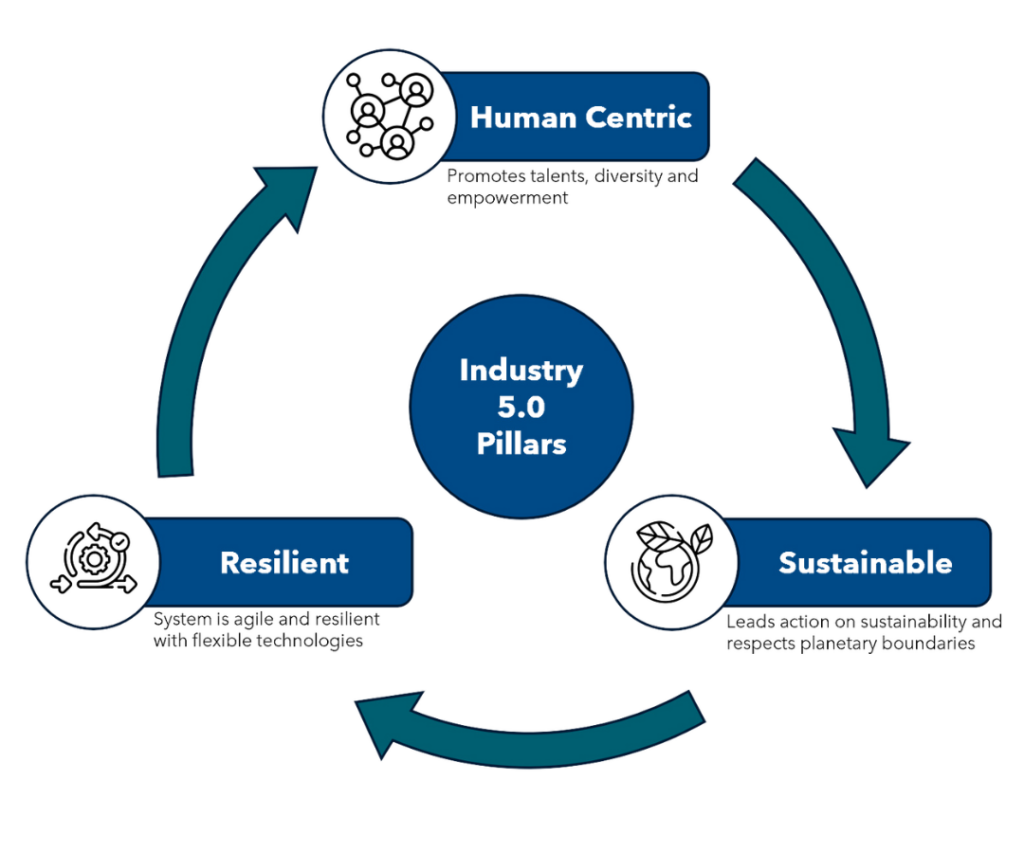

Industry 5.0

Industry 5.0 represents the next evolution in manufacturing, focusing on human-centred, sustainable and resilient production.

Industry 5.0 builds on Industry 4.0 by integrating advanced technologies like AI, IoT, collaborative robots, and digital twins with a focus on empowering workers, enhancing collaboration between humans and machines, and prioritizing environmental sustainability.

Unlike its predecessor, which emphasized automation and efficiency, Industry 5.0 aims to create smarter, more adaptable manufacturing processes that value creativity, employee well-being, and resource optimization while reducing waste and environmental impact. It bridges technology with human ingenuity to drive innovation and sustainable growth in the manufacturing sector.

Georgian College is leading in Industry 5.0

Hamid Dehkordi, Ph.D., P.Eng., a researcher in industrial simulation with Georgian’s Research and Innovation department, examines opportunities presented by Industry 5.0 and highlights how the department is helping industry partners navigate this transition by supporting the adoption of cutting-edge technologies.

Read Hamid’s full journal publication Industry 5.0: The True Power of Human and Machine Intelligence.

Semi-annual Industry Partner Advisory Group

The centre hosts a prestigious semi-annual Industry Partner Advisory Group, bringing together leaders from manufacturing and industry across the region to Georgian College.

This gathering serves as a vital forum to discuss emerging trends, challenges and opportunities in manufacturing, ensuring the centre remains aligned with the evolving needs of the sector.

By fostering collaboration and open dialogue, the Industry Partner Advisory Group provides invaluable insights, enabling the centre to anticipate industry demands and strategically plan innovative solutions to keep businesses at the forefront of technological advancements. This partnership underscores the centre’s commitment to driving regional leadership in manufacturing innovation.

Here’s what I can say about working with Georgian – just ask.

We asked the question and Georgian cued up the time for us.

Steve Loftus,

Innovative Group of Companies

We use (digital) twins to vet applications before putting robots on the floor. It’s powerful in ensuring ROI before implementing.

We’re eager to continue our collaboration and support Georgian College in creating a state-of-the-art facility that will drive regional manufacturing innovation.

Rob Peden,

Advanced Motion & Controls Ltd.

Digital twinning means making things right the first time.

Industry needs more mechatronics professionals with AI skills.

Guy Dulude,

Siemens

Value-added: Shaping the future of manufacturing in Central Ontario

The Centre for Industrial Simulation and Prototyping will address the unique needs of Central Ontario’s manufacturing sector, which is growing at over twice the provincial and national rates.

Serving over 4,000 regional manufacturers, the centre will drive innovation through Industry 5.0 technologies like AI, IoT, and digital twins, enabling businesses to adopt sustainable, human-centred, and efficient processes critical for global competitiveness.

Small and medium-sized enterprises (SMEs) will benefit from access to state-of-the-art tools, expertise and training, helping them overcome barriers like high costs and skills shortages. By fostering strong collaborations with regional partners and organizations, the centre will create a robust innovation ecosystem, supporting mentorship, funding opportunities and commercialization pathways.

With a focus on sustainability and workforce development, the centre will promote eco-friendly practices, resource efficiency, and advanced skills training, solidifying Central Ontario’s position as a leader in advanced manufacturing and Industry 5.0 adoption.

Skills training for a future-ready workforce

Empowering the next generation of innovators

Student training is at the heart of the centre’s mission to support innovation and drive research excellence. By immersing students in real-world applied research projects, the centre provides unparalleled opportunities to develop critical problem-solving, leadership and collaboration skills. Over five years, 100 students will gain hands-on experience working with cutting-edge technologies like digital twins, AI, and collaborative robotics, preparing them to meet the demands of Industry 5.0.

Aligned with Georgian’s mechatronics, mechanical, electrical, and computer studies programs, the centre offers a seamless pathway for students to transition from academic learning to practical applications. Through their involvement in industry-led projects, students will gain valuable exposure to innovation cycles, project management, and professional networking opportunities, equipping them for leadership roles in the advanced manufacturing sector.

Building an inclusive and equitable learning environment

The centre is dedicated to building a welcoming, fair and accessible environment where all students can succeed. Through targeted recruitment, it actively engages equity-deserving groups via Georgian’s Equity, Diversity, Inclusion & Belonging (EDI&B) department, Indigenous Resource Centre, and International Centre. Transparent selection processes and fair evaluation criteria ensure opportunities are available to candidates from all backgrounds.

Team members receive EDI&B training and immersive empathy exercises, such as VR-based modules, to foster understanding and allyship. Advanced technologies, like AR glasses, are used to create workspaces tailored for individuals with disabilities or neurodivergent traits, reducing barriers to participation.

By embedding inclusivity into every aspect of its operations, from mentorship to continuous feedback and improvement, the centre ensures students from diverse backgrounds gain equitable access to valuable learning and career opportunities.

Industry projects: Proven success

Arc Skis

Student training is at the heart of the centre’s mission to support innovation and drive research excellence. By immersing students in real-world applied research projects, the centre provides unparalleled opportunities to develop critical problem-solving, leadership and collaboration skills. Over the next five years, 100 students will gain hands-on experience working with cutting-edge technologies like digital twins, AI, and collaborative robotics, preparing them to meet the demands of Industry 5.0.

Read full blog post here.

Beaver Rock Roastery

Beaver Rock Roastery collaborated with Georgian to refurbish two older K-Cup filling machines to improve efficiency, reduce waste, and meet North American safety standards.

Georgian and Beaver Rock Roastery are currently collaborating on designing, manufacturing, commissioning, and integrating a fully automated, multi-featured modular setup for filter embedding and K-Cup filling/sealing equipment to further improve internal operating efficiencies, expand Beaver Rock Roastery’s offering for their brands and Private Label customers, and commercialize the equipment and supplies for sale into the marketplace.

Read more here.

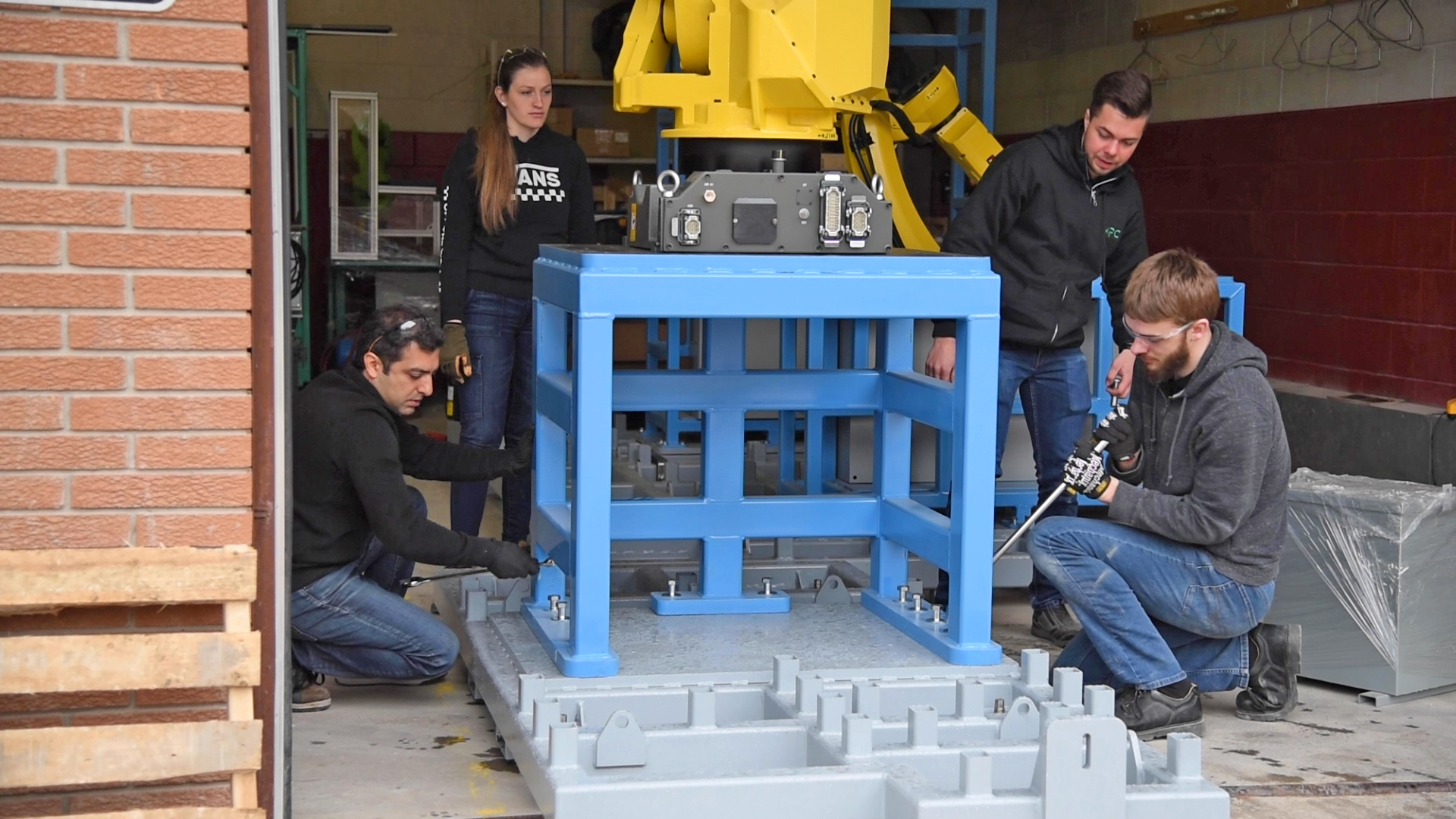

Molded Precision Components

Molded Precision Components (MPC) partnered with Georgian’s Research and Innovation team to develop a robotic cell for their new cube molding machine. This advanced system integrates robots, feeding systems, inspection stations, and storage systems to enable MPC to expand its product line and grow as a company.

Georgian’s students and faculty collaborated on designing, manufacturing, assembling, and programming the system. Despite challenges posed by COVID-19, the team continued their work in a safe environment, producing an impressive design in a short timeframe.

This collaboration showcases the talent and capabilities of Georgian’s students, faculty and staff in driving innovation with community partners.

Honda of Canada Mfg.

Honda of Canada Mfg. (HCM) has been collaborating with Georgian to design, manufacture and integrate a robotic cell for banjo bolt assembly, which is currently a labour-intensive and human-oriented job at the HCM plant to improve productivity and efficiency.

The critical factors to success are meeting quality assurance, maintaining safety requirements, and achieving a specific cycle time.

This unit also helps students and faculty to become familiar with the advanced technologies that are currently being implemented and applied at HCM.

Environmental Systems Corporation

Environmental Systems Corporation partnered with Georgian to develop a display that interacts with the clean room and monitors, logs and graphs critical data points, such as temperature, humidity and differential pressure, with remote monitoring and predictive maintenance capabilities.

Environmental Systems Corporation piloted SmartCritical™ at a major pharmaceutical manufacturer in the US.

Just over 100 units have been installed at Fusion Pharmaceuticals in Hamilton, ON (May 2023).

Central Painting

Central Painting has been collaborating with Georgian to develop a progressive, integrated web-based application (web app) that allows their workers to efficiently track progress and share information, while also enabling fast and accurate reporting and analysis.

The project is currently in the commercialization stage, and a group of experts from Central Painting, mentors from Georgian’s Henry Bernick Entrepreneurship Centre (HBEC), and faculty leads from the college’s Research and Innovation team, along with the students, are working together on a commercialization plan.

Looking ahead: Future planning and leadership at the centre

The Centre for Industrial Simulation and Prototyping is built on a foundation of strategic planning, experienced leadership and alignment with Georgian College’s Strategic Plan and Vision 2030. With a skilled research team specializing in advanced manufacturing, mechanical simulation and electronics, the centre ensures high-quality service delivery and impactful applied research projects.

By integrating student and faculty engagement, the centre offers immersive learning opportunities that align with Industry 5.0 technologies, preparing a future-ready workforce while advancing regional innovation. Its four-tier service model (insight, conceptualization, build and mastery) provides tailored support for client organizations, from initial consultations to advanced training, ensuring scalable and accessible solutions.

Supported by Georgian’s funding and resources, the centre fosters sustainable partnerships and reduces barriers to technology adoption for regional manufacturers. This cohesive approach ensures the centre plays a pivotal role in driving innovation, enhancing competitiveness, and shaping the future of advanced manufacturing in Central Ontario.

Research excellence: Strong foundation for investment

Georgian’s proven research expertise and track record in innovation position the Centre for Industrial Simulation and Prototyping as a hub for investment and growth. With over $20 million in government and industry funding secured since 2016, Georgian has consistently delivered impactful applied research projects. Between 2019 and 2023 alone, the Research and Innovation department engaged in 140 advanced manufacturing and digitalization projects with over 50 industry partners, demonstrating its ability to foster meaningful collaborations and deliver results.

The centre builds on Georgian’s established strengths in areas like Industry 5.0 technologies, digital twins, robotics, and advanced data analytics. Its state-of-the-art facilities, including a rapid prototyping lab, microgrid, and mechatronics lab, provide clients with access to cutting-edge tools and technologies. The research team’s deep expertise in mechanical and electrical engineering, industrial simulation, and smart manufacturing ensures high-quality service delivery and innovative solutions.

This foundation of excellence and readiness will attract investment by offering clients confidence in the centre’s ability to de-risk technology adoption, accelerate innovation, and drive economic impact. With strong partnerships, a proven cost-recovery model, and a focus on sustainability, the centre is poised to generate sustainable revenue while contributing to the region’s growing manufacturing sector.

Shared vision: Built for excellence and inclusion

The Centre for Industrial Simulation and Prototyping is driven by a team of highly qualified professionals with decades of experience in advanced manufacturing, automation, and Industry 5.0 technologies.

Equity, diversity and inclusion are central to the centre’s approach to recruiting and developing talent. The centre proactively engages equity-deserving groups through Georgian’s EDI&B department and resource centres, ensuring diverse representation at all levels. Recruitment panels are designed to minimize bias by including members from equity-deserving groups and evaluating candidates based on a broad range of achievements, not just traditional metrics like grades.

All new hires participate in comprehensive EDI&B training, including modules on allyship and immersive VR empathy exercises, to foster an inclusive and collaborative workplace culture. Additionally, the centre uses advanced technologies like XR to create accessible environments for individuals with disabilities or neurodivergent traits, ensuring equitable participation.

Mentorship programs further support professional growth, pairing team members with mentors aligned to their career goals. Annual reviews of EDI&B practices by leadership ensure continuous improvement, fostering a welcoming and inclusive environment for all personnel. This intentional approach to EDI&B ensures the centre attracts and retains top talent while setting a standard for inclusive innovation in manufacturing.

Laleh Khodaparast, MEM, PMP

Laleh is a strategic leader with a strong track record of advancing applied research initiatives and fostering innovation through industry collaboration. As Director, Research and Innovation at Georgian College, she oversees projects that drive technological advancement and socio-economic growth. Under her leadership, the department has cultivated partnerships with industry and community stakeholders to address pressing challenges, including the integration of emerging technologies such as artificial intelligence (AI) into applied research initiatives.

Hamid Dehkordi, Ph.D., P.Eng.

Hamid specializes in industrial simulation and virtual prototyping, with expertise in digital twins and smart manufacturing. His dedication to cutting-edge innovation inspires students and partners to push the boundaries of what is possible in manufacturing and automation.

Majid OstadRahimi, Ph.D., P.Eng.

Majid is a specialist in electrical engineering, simulation and control systems, with certifications in Siemens Mechatronics and extensive experience in industry collaborations. He is passionate about leveraging advanced technologies to drive innovation and help students learn real-world applications in Industry 5.0.

Sanjeev Kumar, MTech (Software Engineering), MSc. (Artificial Intelligence & Machine Learning), MCA, MSc. (IT), MSc. (Mathematics), PGM (GIS), PG (AIDI)

Sanjeev Kumar has over 18 years’ experience in the field of information technology with specialization in artificial intelligence (AI) in industrial applications. Sanjeev is working as a part-time professor in the Artificial Intelligence – Architecture, Design, and Implementation program at Georgian College and is a researcher in the Research and Innovation department. Sanjeev’s specialty lies in designing and developing complex industrial AI applications. He has diverse international experience as an IT consultant in the manufacturing, oil and gas, and electric sectors in India, the USA, the Middle East and Canada.

Dr. Amir Baghaki, P.Eng.

Amir is an expert in electrical engineering and system design, specializing in simulation and control systems. As a professor, he has extensive experience in digital and control systems commissioning, with certifications in Siemens Mechatronics (SMSCP) Levels 1 and 2 and ANSYS low- and high-frequency applications. He also collaborates with industry partners like ANSYS and SimuTech on advanced simulation projects.

Andrew Cywink, C.E.T., M.E.

Andrew brings expertise in system design, automation and renewable energy systems, with certifications as a Red Seal Electrician and Master Electrician. His passion for sustainable solutions and hands-on learning equips students and partners with the tools to succeed in an evolving manufacturing landscape.

Felix Yuen, LL.M. (IP), FCIArb

Felix is a seasoned intellectual property (IP) consultant and policy advisor specializing in organizational IP and monetization strategies. At the Henry Bernick Entrepreneurship Centre, his focus is to develop and deliver programs that strengthen the IP knowledge and capabilities of Georgian College, its industry partners and community clients.

Amanda Mejia, B.Sc.

Amanda specializes in business development, national and international partner relations, and digital and traditional marketing. Her focus is on bringing opportunities to the Simcoe, Grey and Bruce Counties.